New Construction Warranty Inspection – Dirty Air Filter – Sarasota/Bradenton

Not all Home Inspections and Home Inspectors are Created Equal – Sarasota/Bradenton

Not all Home Inspections and Home Inspectors are Created Equal – Sarasota/Bradenton

Despite licensing and state and association standards of practice, not all home inspections and home inspectors are created equal. There is a large amount of variation in the knowledge and background of inspectors, what is inspected during the inspection, and how that information is reported. Many home inspectors do come from construction or trade backgrounds, but many do not, and while it is not absolutely necessary, the knowledge gained while working in a related trade is that much more beneficial to the inspector and their clients. Most association and state Standards of Practice exclude inspection of certain systems and components, but some inspectors will still test and offer comments on these items as a curtesy. Some Inspectors will go the extra mile to provide a detailed and quality service while others just provide the minimum. Reports range from checklists that provide little detail about an issue, maybe a vague description of the location and minimal or no pictures, while others provide comprehensive reports with pictures and details of almost every issue and location. A great way of knowing what you can expect from your home inspector is to ask them for a Sample Report. There is not necessarily a right or wrong way to inspect and report because client needs vary just as much. Some people are ok with just the basics, and some want all the details. Purchasing a property is the largest investment most people ever make and not only is the inspection and report an opportunity for the buyer to learn about the condition of their potential investment, but it is also a powerful negotiating tool. A detailed report full of pictures helps ensure that the report is read and understood by all parties and it makes it harder to argue the existence of a problem as well as it making it easier for contractors to offer estimates and find the areas to repair.

One of the most important aspects of your inspection reports are the disclaimers/limitations. Sometimes an area is unable to be inspected at the time of inspection due to safety concerns or environmental conditions. However, the inspector must note the area that was unable to be inspected and why so that the buyer can have the opportunity to have the area inspected before the expiration of their inspection contingency.

The following incident, in the Sarasota/Bradenton area, left a buyer/now homeowner with tens of thousands of dollars in repairs. As a little bit of background to this story, we previously provided a home inspection to a buyer that was working directly with the seller who was also the listing agent. The property was a 1920’s home that had been poorly flipped. After only inspecting the roof, exterior and the detached garage, significant and substantial defects were observed, and the buyer made the decision to not proceed with completing the inspection or the purchase of this property. The buyer was very pleased with the services we provided and said they would be using us on their next inspection.

Several months later we received a call from the buyer, and they explained that they had purchased a home (built in the late 1990’s, masonry block home on a crawlspace) and have been living in it for three weeks now. The buyer decided to hire a realtor for this purchase, and the agent told the buyer that they had “their guy” that they always use for home inspections, and that the buyer should only use him. Everything moved forward, the buyer closed on the property and moved in. The first night in the home the buyer went to wash a load of laundry and the house almost burned down as the laundry room and hallway started filling with smoke! A repair person came to the property and got into the attic and it was blatantly obvious that the dryer vent had been disconnected in the attic, lint was everywhere and the vent pipe was blocked with lint resulting in a huge fire hazard that was not reported in the inspection report. Several days later the buyer awoke around midnight to half of the home flooded with an inch of water. It turns out that a pipe in the wall at the master shower had separated and caused the leak, the byer dried up the water and had the pipe repaired. To be fair to the inspector this issue may have been difficult to identify with a visual inspection if it was not actively leaking at the time of the inspection. They buyer then decided to have pest company come out to get the home on a maintenance plan and while the pest inspector was in the attic he noticed that there was a large amount of pine needles, pine cones and pine tree bark in the attic below an area of roof sheathing that appeared to have been replaced indicating that a tree may have fallen on the roof.

The buyer was very upset and extremely concerned about what else may have been missed during the inspection, so she wanted us to come out and reinspect the property for her peace of mind. We completed the inspection of the home’s interior, not including the crawlspace which we save for the end. The previous inspector included one picture from the crawlspace that showed the floor system insulation had partially fallen and the comment in the report that “insulation had fallen” which implies that they inspected the crawlspace as there were no disclaimers indicating otherwise. We proceeded with our crawlspace inspection and immediately, right at the entrance to the crawlspace directly above where the previous inspector had taken his insulation picture, there was an actively leaking bathtub drain that had rotted completely though the engineered floor joist. As we continued inspecting the crawlspace it was apparent that almost all the floor system insulation had fallen to the ground and needed to be replaced as well as the fact that there was no moisture/vapor barrier installed. It turned out that every bathtub and toilet was and had been leaking and resulted in subfloor damage. One of the issues we had discovered inside was that the bathtubs were severely corroded and rusted through in areas, and this was even more apparent from the crawlspace and the bathtubs may need to be replaced. We also discovered extensive evidence of wood destroying organism activity consisting of mud tubes on the concrete masonry unit foundation walls that continued into the walls of the home and frass (termite fecal pellets) and extensive wood damage to the engineered floor joists. There was also an area where water was flowing into the crawlspace and the vents were blocked by the exterior grading which was causing elevated humidity levels resulting in mold growth on the underside of the floor sheathing.

Unfortunately for the buyer, all these conditions were un-reported in the previous inspector’s inspection report and the inspector may not have even inspected these areas. The pest inspection company also did not appear to have inspected the crawlspace or identified these conditions. The previous inspector was avoiding talking to the buyer, denied responsibility and stated they were getting a lawyer. Now the buyer is responsible for these extensive repairs with limited options to recoup the associated costs. If this buyer had been well informed about these conditions or any potential inspection restrictions/limitations, they may not have purchased the property, or they would at least have had the opportunity to negotiate the repairs prior to closing. This buyer has been let down by the people they hired to protect their interests. When spending your life savings or taking on significant debt from a mortgage, the cost of a quality home inspection is insignificant to avoid financial ruin. Protect yourself and your investment by asking questions and researching your potential inspector, making sure they provide the level of service you expect.

Make Sure Your Insurance Inspections Are Current!

1987 Coleman Package Unit A/C

While performing home inspections in the Sarasota and Bradenton area we experience a vast variety of homes. We inspect new construction, historic homes, manufactured homes, and homes of all ages and styles. Each home tells a story about what its been through and experienced over the years. One of the greatest stories is when equipment and systems were built to last. Recently we inspected a home with a 1987 Coleman package unit air conditioning system that was still blowing cold air to this day. That is 32 years old! The industry average life expectancy for an HVAC condensing unit in Florida is 10-12 years. Routine maintenance, which is commonly neglected, is a big factor in keeping these systems in good working order. Even so, products that have been manufactured more recently are just not built to last. We have become a disposable society where there is minimal incentive to repair when it can just be replaced, and replacement is where the money is for manufacturers and many service providers. The purchase of a home is the greatest investment most people will ever make. We encourage you to love, care for and maintain your investment so that it will retain its value and provide a safe and protective environment for you and your family. Contact us Today for an Annual Home Maintenance Inspection to help identify areas of your home that need attention. www.CornerstoneHomeInspectionGroup.com

What is Wind Mitigation

What is wind mitigation and how does it affect me and my home? Did you know a wind mitigation inspection could save you money? Wind mitigation is a strategy of implementing design, construction techniques, and products to mitigate or reduce the effects of wind and wind related damage to a structure. After Hurricane Andrew, Florida passed a law requiring insurance companies to offer discounts or credits on insurance rates depending on existing building features and improvements or upgrades that reduce damage from wind. The Uniform Mitigation Verification Inspection Form OIR-B1-1802 is a standard form used by inspectors and provided to insurance companies to document the wind mitigation features of a structure and the form is valid for 5 years provided no material changes have been made to the structure. The form has specific features that are to be inspected for and photo documented to prove the existence of these features. The first section of the form regards to when the structure was built and whether the structure was built according to improvements adopted in the 2001 Florida Building Code. The second section is about the type of roof covering and date in which it was originally installed or replaced. The third section is roof deck attachment which looks at the type of fasteners and fastener spacing used to secure the roof deck sheathing to the roof trusses. Many options for roof to wall connections exist and have been used throughout history and have been grouped into several categories based on the strength of the attachment method. Section four regards to how the roof trusses are attached to the walls of the home. Sections three and four combined determine the approximate amount of uplift force a roof structure can handle. Section five reviews the roof shape and how wind interacts with that roof shape. A hip or pyramid shaped roof will allow wind to flow over the structure better than a big gable end that wind can push against. Section six relates to the presence of a secondary water resistance barrier such as peel and stick underlayment’s which offer increased protection from water intrusion and damage. The final section of the form regards to the presence of opening protection in the form of impact windows and doors or shutter systems. In general, all openings require protection to receive credit. Any features noted in the wind mitigation inspection report should be verified with photographic evidence. A typical wind mitigation inspection takes between 30 and 45 minutes to complete and can save you a considerable amount of money on your homeowner’s insurance premium. If it has been more than 5 years, if you have recently replaced your roof covering, or if you have added opening protection to your home you should consider getting an updated wind mitigation inspection report to ensure that you are receiving all possible discounts or credits. Contact us today to schedule a wind mitigation!

For Sale by Owner Sign Posts

Are you selling your home “For Sale By Owner”? We offer sign post installations with an included “For Sale by Owner” sign panel. Although we always recommend using a licensed real estate professional, we believe you should still be able to market your home like a professional while selling it on your own. We can also provide you with a pre-listing inspection so that you can address any issues prior to the sale and utilize the inspection report in your marketing. Visit www.CornerstoneHomeInspectionGroup.com or call 941-993-0216.

Choose a CMI

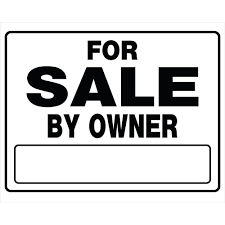

New Construction Missing A/C Duct

Does your new home need an inspection? New doesn’t always mean done right or done at all. Mistakes and oversights commonly occur during construction which is why it is so important to have your new construction home inspected. Here is an example that drives that point home. We were contacted to perform a home inspection after a buyer had moved into their new construction home and the roof started leaking. During the inspection, several defects were observed with the roof and throughout the home, including, a missing A/C duct. A hole was cut, and a duct collar was installed in an air conditioning distribution box and a register was installed in the kitchen pantry, but no duct connecting the two was ever installed. This condition resulted in wasted electricity and conditioned air being released into the attic and hot attic air entering the home through the air register, further reducing the efficiency of the air conditioning system. Luckily the home was still within its warranty period for repairs by the builder and this issue was caught before too much time had elapsed and more money in unnecessary cooling/heating costs was lost. We always recommend having a home inspection whether it’s a new home, older home or a home you currently live in because in most cases, including this one, the value of the inspection findings far exceed the cost of the inspection itself. Contact us today at 941-993-0216 to schedule your home inspection.

Dryer Vent Safety

Your next load of laundry could burn your house down! Have you had your dryer vent cleaned recently? Your clothes dryer heats and evaporates the remaining water (more than a gallon for heavy loads) from your clothes using either an electric heating element or a gas burner. For a dryer vent to function properly it has several requirements: it must be properly connected and vented to the exterior of the home. It should not be restricted, kinked, or crushed in any way to allow air to flow freely, and it must be cleaned or serviced regularly to remove the lint that builds up on the walls of the vent. Lint is made up of clothing particles such as cotton and polyester which is extremely flammable and when it builds up it can cause reduced drying efficiency and ultimately cause the dryer to overheat and catch the lint on fire. Fires typically start within the dryer first and then spread through the ventilation duct and to other areas of a home. Statistics from the National Fire Protection Agency indicate that in 2005, dryers were responsible for 13,775 house fires, 418 injuries, 15 deaths and $196 million in property damage. Most of these fires were caused by a failure to clean and maintain lint from dryer vent ducts. Currently, dryer vent ducts are required to be made of rigid metal ducts with smooth walls to help prevent accumulation of lint. Flexible “transition” ducts are only allowed to make the connection between the dryer and rigid ducting. We inspect dryer vents for a number of other requirements as well, to ensure the proper installation and operation of your dryer vent and the safety of you and your home. We also recommend annual cleanings of your homes dryer ducts. Contact us today to schedule your home inspection.

First Time Home Buyer

Are you a first time home buyer? We want to help you get started off on the right foot with maintaining your investment. We will show you where main water and electrical shut-offs are so that in an emergency you know where they are located and how they operate. We will also show you current and future maintenance items that may require immediate attention or annual maintenance.

Contact Info

Licensing Info

Florida Licensed Home Inspector #HI9508

InterNACHI ID#16013009

Florida Licensed Mold Remediator #MRSR3271

Services

- Home Inspections

- New Construction

- Wind Mitigation

- 4 Point Insurance

- Thermal Imaging

- Roof Certification

- Water Testing

Recent Comments